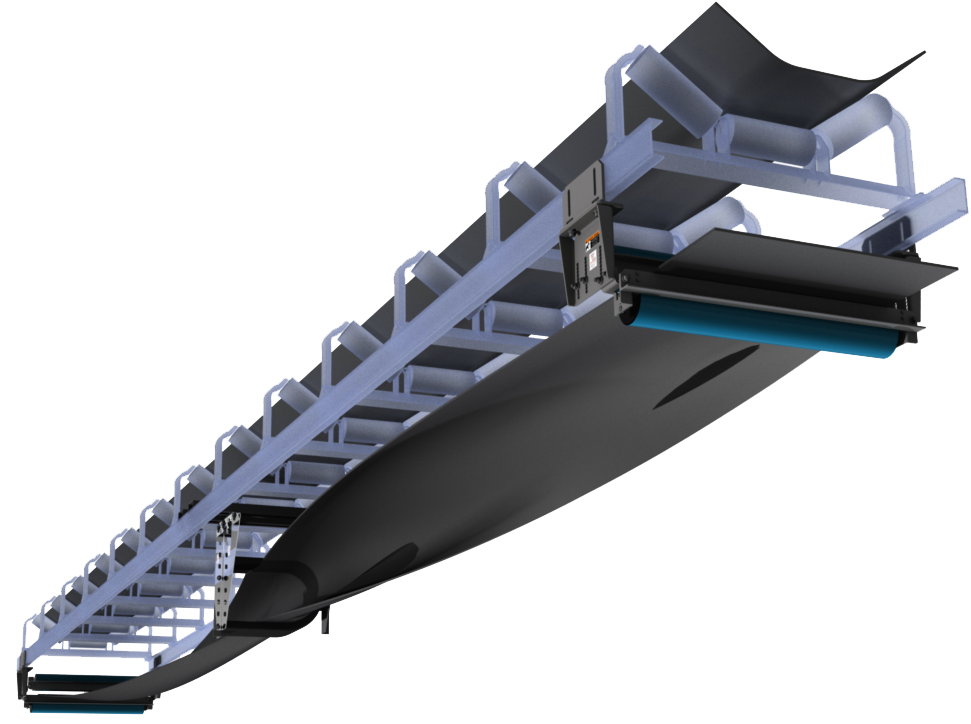

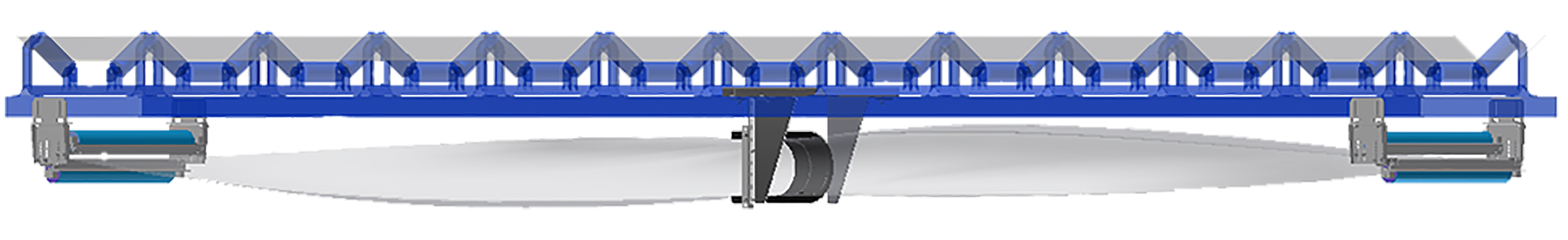

SPAR3 Belt Turnover System

A belt turnover is a simple, effective and safe solution for reducing maintenance, contamination and dust. In addition, it can extend the lifespan of several key conveyor components. Having the return belt turn over so that the dirty side is facing up prevents carryback from building up on the idlers or falling beneath the conveyor. This solution is particularly useful in tunnels, in areas hard to access or for long conveyors.

Why turn a belt over with the SPAR3?

- Reduces amount of carryback falling under the conveyor by over 90%

- Limits cleaning operations of the return side to only two points (head and tail)

- Particularly useful in tunnels or other locations where belt cleaning is difficult

- More than doubles the lifespan of return idlers

- Eliminates build-up on return idlers, thus improving belt alignment

- Extends belt lifespan

- Fewer cleaning operations means having fewer employees being in proximity with the conveyor

Is the SPAR3 safe? Will it break my belt?

- For years, industries around the world have been using belt turnover systems. The Brunone solution stands out owing to its simple design and effectiveness. The SPAR3 was specially designed to safeguard belts and improve conveyor operational efficiency. All our slider parts are made of ultra-high density polymer specially designed to reduce friction.

- Our team of experts, who have installed the SPAR3 on thousands of conveyors, can advise you on the technical aspects of your belt turnover needs.